Can you share a bit about your journey in the AEC technology industry and how you got started?

«I started in the industry as an end user in Sweden many years ago. It was, in a way, at the beginning of the machine control journey where a lot of 2D systems were being deployed foremost on excavators (Sweden was at the forefront for this specific application). At that time, 3D was a true add-on, which meant that you had two displays in the cabin, one dedicated to 2D functionality linked to another panel for 3D visualisation. Supplying the 3D features with accurate positioning data required GNSS positioning systems that were as fast, robust, and accurate as possible.

Already at the beginning of digitalisation, it was clear that an ecosystem was needed as 3D data was used not only for machine control systems but all different technologies in the field that utilised the same data (which was, and still is, of the highest importance).

As an example, the desktop software needed to be able to import/export the same format as the field tools, no matter if it was a GNSS rover or a “machine tool”. To make it even more complicated, there were no standard data formats…. Why did the focus shift towards «closed» ecosystems with a secondary consideration for import and export functionality in general?

As the journey continued, the machine control part got more unified with one display, one software in the cabin, and faster, more robust GNSS options (adding more constellations and channels & supporting many more machine types, etc). In addition, various import/export capabilities and a growing understanding of the challenge for connected ecosystems emerged as mixed fleets became more and more common.

During the beginning of this journey, it was more of a “push” effect from all technology manufacturers, but as the technology matured and the “pull” from the market grew faster, many of the OEMs got connected as well. (Some earlier than others)

Even if I have been in this industry for a long time and in many ways, thought we would be a bit further by now…it still excites me as we have so much more to do for our customers.

This is an industry that needs all of us to work towards sustainability, connecting all the ecosystems, improving the ease of use, improving safety and finally, whatever projects are being built – be on time, on budget & specifications to make sure that the final infrastructure product has the right lifespan.»

How has technology transformed the way projects are conceptualized, planned, and executed in the AEC industry during your career?

«This has been an evolving part as well as everything in the AEC industry during my career; improvements & new software have not just evolved but transformed ways of conceptualising projects, and stronger software packages have been created for planning and executing.

For the planning & executing part, there have been large strides where significant progress has been made to enable real-time feedback loops. This not only enhances productivity but also facilitates a comprehensive understanding of planned and executed aspects of the job. These processes are seamlessly interconnected through cloud solutions, enabling convenient access and exchange of information in “real time”. (Or as close as it can be right now)»

As someone deeply involved in AEC tech, what challenges have you encountered, and how have you overcome them?

«I think that, in general, technology moves quite fast, which is a challenge in itself. This implies that progress may be faster in certain regions, demanding tech providers to adapt accordingly. However, the global pace of advancement may not be uniform calling for an approach that accommodates varying speeds of progress worldwide.

On top of this, all tech providers are always looking at how they can be disruptive or lead a change to gain an edge or create a new offering, but at the same time, not be pricing themselves out of the market.

All of the above are true challenges, as well as knowing when a technology is mature enough to be used in certain environments/markets and considering local laws and regulations. This has a big impact on tech providers; even if it’s possible to create a solution/offering, it might not be the right time due to the above challenges.

It many times comes down to timing.

The answers on how to overcome some of these are simply to have or to gain very strong industry knowledge, be very close to the market as well as be part of discussions with regulatory organs in many key countries/markets but saying “simply” is clearly oversimplifying the challenge, but still, that is partly the answer to the question.»

Considering the current technological advancements, where do you see the future of AEC technology heading in the next 5-10 years?

«First of all, I think that we will see much more collaboration and partnerships within the AEC industry. No one provider can solve all the challenges that we all face; it is a mix of technology advancements and several steps of autonomy in combination with AI deployed in the right places at the right time and simplifying the tech usage for more users in the entire construction process.

This will create transparency and more people being on the same “page”, which also will help with tech adoption overall, which is highly needed to attract our younger generations across the different parts of our industry.

Within this timeframe, I see even more technology being adopted in several steps, more emphasis on connected ecosystems and hopefully also some very strong strides when it comes to standardisation of formats to create even more transparency and data flow.»

Collaboration is crucial in AEC projects. How have collaborative tools and platforms evolved, and what role do they play in enhancing project efficiency, especially with diverse stakeholders like designers, engineers/surveyors, project managers and client owners?

«Yes, as I touched a bit on above, one of the key factors for successful planning/execution/handover is for sure collaboration tools across the phases of the project.

Even if good strides are being made, we are still, in many ways, missing a “standard toolset” for a seamless project transition from inception to finalisation. With all the different stakeholders and all the different personas on-site or off-site in mind, however, if we only look at the construction phase, a few tool options are emerging (some new, some have been growing over time) which have a clear goal of connecting the entire construction data flow/handling with efficiency as the main focus. This is good news as we need to see to it that the customer’s daily challenges become less complex.

The focus for the project/customer should be on how to complete the project on time, on budget and on specification rather than focusing on data handling complexity where a lot of errors can occur. (And time is wasted)»

Sustainability is a growing concern. How do you perceive the role of AEC technology in promoting sustainable practices within the industry?

«Sustainability is a huge topic for all of us, and by using small parts of existing AEC technology, we are taking steps towards sustainability improvements, but it is clear that the technology providers have a great role to play in educating what the technology does for the environment. Just to name a few, utilising digital technology provenly improves resource utilization, minimizes waste, and reduces environmental impact throughout the project lifecycle. This collaborative approach between technology providers and industry stakeholders is crucial for fostering a greener and more sustainable future for the construction sector and beyond.»

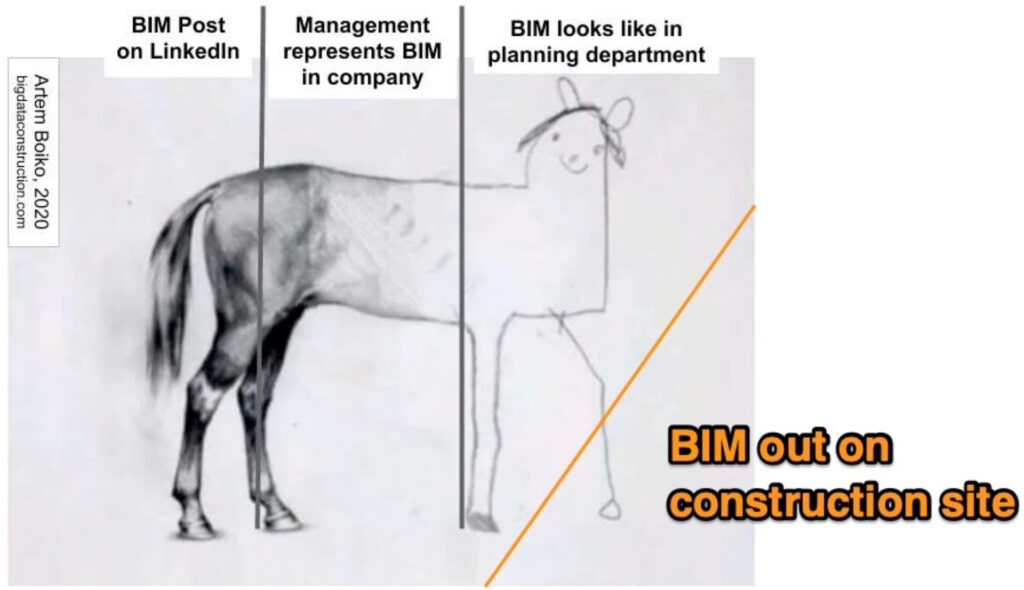

With the rise of BIM (Building Information Modeling), how do you think it has impacted the design and construction phases of AEC projects, and what do you anticipate for its future?

«BIM has been a subject for a long time now, and I think it has gotten parts of the evolution & discussion to be where it should be.

Sometimes, I do feel that we are not as fast as we should be, but once again, we have so many aspects that need to be considered; hence, it is taking more time.

Looking towards the future, I anticipate BIM will continue to play a pivotal role in the AEC industry to achieve our sustainability and quality goals. We can expect further integration of BIM with emerging technologies such as artificial intelligence, machine learning, and augmented reality, unlocking even greater capabilities for project stakeholders.»

As technology advances, there’s often a learning curve for industry professionals. How can the AEC sector ensure a smooth transition for its workforce into more tech-driven practices?

«To ensure a smooth transition to tech-driven practices, the AEC sector should implement comprehensive training programs, collaborate closely with technology providers, and foster a culture of innovation. As mentioned earlier, the main goal must be to make technology accessible and intuitive. Easy to use!

One of the challenges has been an ageing workforce and, at the same time, attracting a younger workforce. Developing “easy to use” tools is needed to solve both.

And even more in the future as you will see tools connected to different stakeholders with a lot of different levels of education. This approach will enable AEC professionals to leverage technology to enhance productivity, efficiency, and overall project outcomes.»

Are there any specific trends or emerging technologies in AEC that you find particularly exciting or promising for the industry’s future?

«I think that would be AI in combination with autonomous technologies/steps. The question will be how fast it will go, as so much attention is on it right now. The question is only what will be accepted and approved for such a conservative industry with a very high safety focus.»

Looking beyond technology, what cultural or mindset shifts do you believe are necessary for the AEC industry to fully embrace and capitalize on technological advancements?

«This is a good question; change can go slow or fast. It is normally a push from tech, and after a while, it becomes a pull effect from the market, and we can see this clearly with tech usage.

However, to truly embrace and capitalise on tech, governmental bodies should be given stronger direction regarding technology usage in any building and infrastructure project. For instance, it would/should not be possible to bid for a job without using digital processes and technology such as machine control & 3D solutions.

I have seen many different ways this can be done in several countries; it drives not only adoptions, it drives a higher standard and quality output, which we all know we need.»

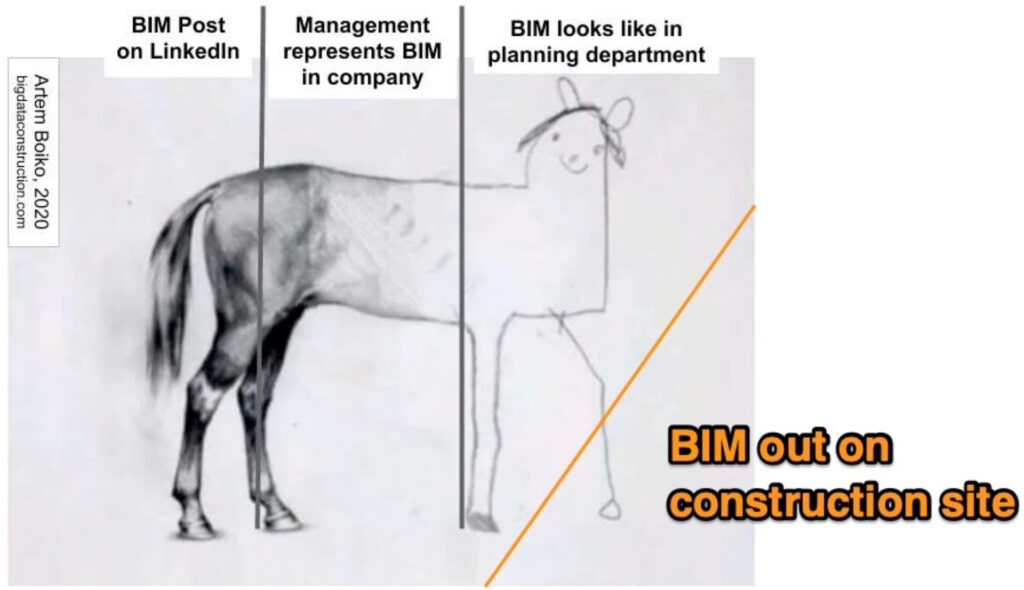

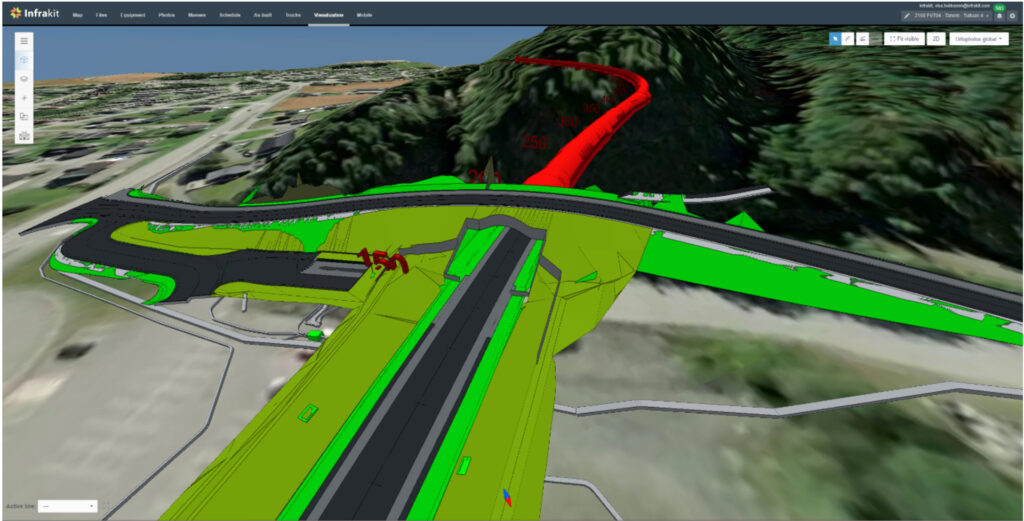

How do you see the role of technology in bridging the gap between the physical and digital worlds within the AEC industry, and what impact do you think this connection will have on project development and execution?

«This is one of the key roles that all tech providers have, to bring the physical and the digital worlds “together”. To me is a big part of BIM or SIM, working from one design model synced with all changes on site, the physical world.

This will have a huge impact on project development and execution; with many different sensors on the several “tools” out in the field. You can get accurate information looping back to the planning and design teams, which, in the end, helps to plan more accurately out in the field and vice versa.

As mentioned above, integrating digital technologies and bridging the gap between the physical and digital worlds in construction promotes greater efficiency and sustainability, reducing waste and providing cost savings.»

Lastly, reflecting on your career, what advice would you give to young professionals entering the AEC technology field today?

«Be bold, be brave and challenge the status quo.

Even if I have been in this industry my entire life, and for sure thought we would have been further in some areas by now, I find it extremely exciting and challenging as we have so much more to do together. Not only improve the current technology landscape but disrupt and challenge how we do it today. It is needed to gain great strides with completely new ways of collecting/exchanging data and collaborating across disciplines and personas in the whole construction process.

Just as an example, think about collaboration (how can 1+1 equal 3), how can more people benefit from what you are doing? How can you change/improve what is done today to become something better?

And most importantly, don’t be afraid to ask more questions.»

Recent Comments