GUEST POST: Turning Point of Digital Infra-Construction

Turning Point of Digital Infrastructure Construction

(Written by Iiro Villman)

Summer, the high season of infra-construction business, is here and news about busy offer calculations and great amounts of projects offers can be heard from all over Finland. The most intense period of the whole year is on-going, but this time maybe even more actively than before. “If this is recession, hopefully it would last even longer”, a sentence heard from one contractor. This indicates that even winter wasn’t too bad for the infra-construction industry. Is the positive news stemming from the contractors, who have been keeping the offers low and – in this way – gotten themselves a lot more work with a smaller salary, or from the fact that they have some competitive advantage over other contractors?

Digitization as an competetice edge: tangible benefits are seen in cost-efficiency

Technology for Everyone

There have been services for digital construction available for everybody’s use for some years already when trying to improve the competitiveness of the market, but still only few have utilized them in full scale. Finland’s major infrastructure contractors have been developing the technology and using the services for years, though. Their initiative and government-supported projects have developed technology to a much needed positive direction in the industry.

Now, however, it seems that the advantages of technology have been noticed among small and medium-sized operators as well. Machine control system sales are accelerating when, at the same time, applications and electrical tools are becoming more and more standards in the field. The benefits of the technology can be seen in the improved cost-effectiveness of projects and thus improving the competitiveness of companies. You see, in today’s contract contests, only few jobs are goldmines for the winning tender already from the beginning.

Total costs of the project are determined at the designing table, but during implementation phase the greatest costs arise from material purchasing and implementing the job itself. It is difficult to lower the material prices since manufacturing and raw materials’ costs are rising continuously. Instead, it can often be seen on worksites that machinery is on a standstill or tasks might have to be done twice due to construction errors or incomplete designs. New technologies provide new possibilities and solutions for lowering working costs and enhancing work efficiency for any project, but especially for projects that have set very low margins in the offer phase.

Professionally skilled staff and active foremen are the key players when talking about work efficiency. But what if the foremen don’t have the time needed to run the worksite with traditional methods? Machine control systems and data transfer applications – which are easy to use – help foremen, and make their tasks easier on-site. When utilized right, devices and applications pay themselves back quickly with work becoming much more efficient.

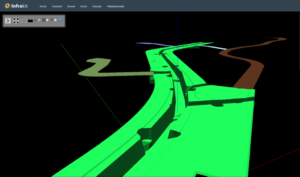

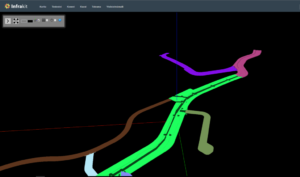

You can view 3D designs in real-time also on Infrakit

Real-time Quality Control

Nowadays project owners have a goal to implement projects with as high quality as possible with the lowest costs possible. Achieving and authenticating the given objective is based on mutual trust between project owners and contractors, even if the owner’s representative or consultant would visit the site often. Most of the end products in infra-construction remain hidden from the surface and it is not always possible to see from the finished structure whether the project was actually completed according to the design.

It’s not my intention to imply only the worst-case scenarios about contractors’ reliability or their ways of producing high quality projects, but to highlight all thepossibilities of improving the worksite’s real-time quality control processes brought by today’s techniques. Work on the construction site is progressing rapidly and getting the as-built data surveyed with the traditional methods to consultants and project owners can often take weeks. In the meantime, many phases have been completed following the possibly incorrect as-built data. Repairs done afterwards are always expensive and, in addition, violate the work that has been done correctly around the incorrect structure.

3D view of the project

Nowadays, project owners require more comprehensive documentation from the contractors just to ensure the usability of the structures. Contractors avoid expensive solutions that seemingly don’t directly affect the final result of their product. They try to come up with easier ways in order to fulfill the project owner’s requirements. For this reason, contractors have acknowledged digital applications, and benefits and possibilities provided by new technology. In order to achieve the desired transparency and comprehensive quality control, real-time applications have been taken in everyday use – at least in public sector’s construction projects. I sincerely wish that the private sector would follow their lead!

3D KOPPI logoThe issues mentioned above are based on stories told by different contractors and on my own experience from the private sector. I, myself, have worked as a site manager in earthmoving projects and seen the ways that tasks could be completed more efficiently with machine control systems and real-time data transfer and quality control. Luckily these kinds of solutions already

exist and new tools are created as we speak. Even the small contractors can get a competitive advantage by taking the newest technologies in use, and work the same way as the big companies.

Founders of 3D-KOPPI Sami Rautkoski (left) and Iiro Villman

The author, Iiro Villman, is the Project Manager of 3D-KOPPI Ltd., 3dkoppi.fi

Editor’s note: This is the 2nd post in our new Guest Post series where infra-construction experts and experienced doers tell about the transformation of infra-construction industry, digital leap and new winds of change in the industry. The posts are written by the authors themselves and the texts have not been edited (except a word-for-word translation into English).