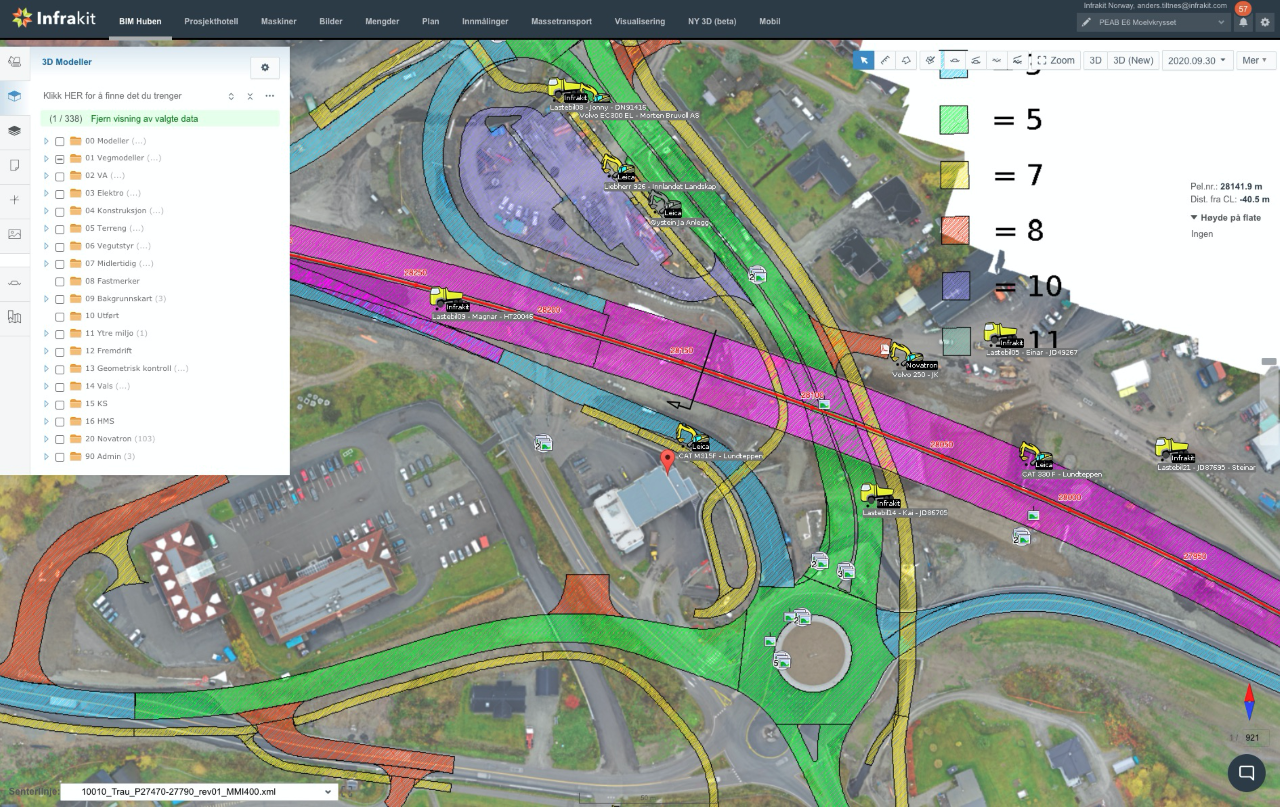

On the E6 Moelvkrysset roadworks in Moelv, PEAB set out to keep production data simple and consistent from day one: machine control models, photos, and updates in one place—without jumping between multiple portals. Infrakit was chosen early and used daily by the survey and production teams.

Results at a glance

“We wanted to have all the machine control in one place. The same applied to photos, models and the updating of new versions.” — Eirik Frimannslund, Survey Manager

“Instead of going through five different portals, it now sticks with one.” — Eirik Frimannslund, Survey Manager

Weekly machine calibration with history tracking and alerts when accuracy drifts outside requirements.

Real-time mass haul visibility with reliable statistics supported by geofencing.

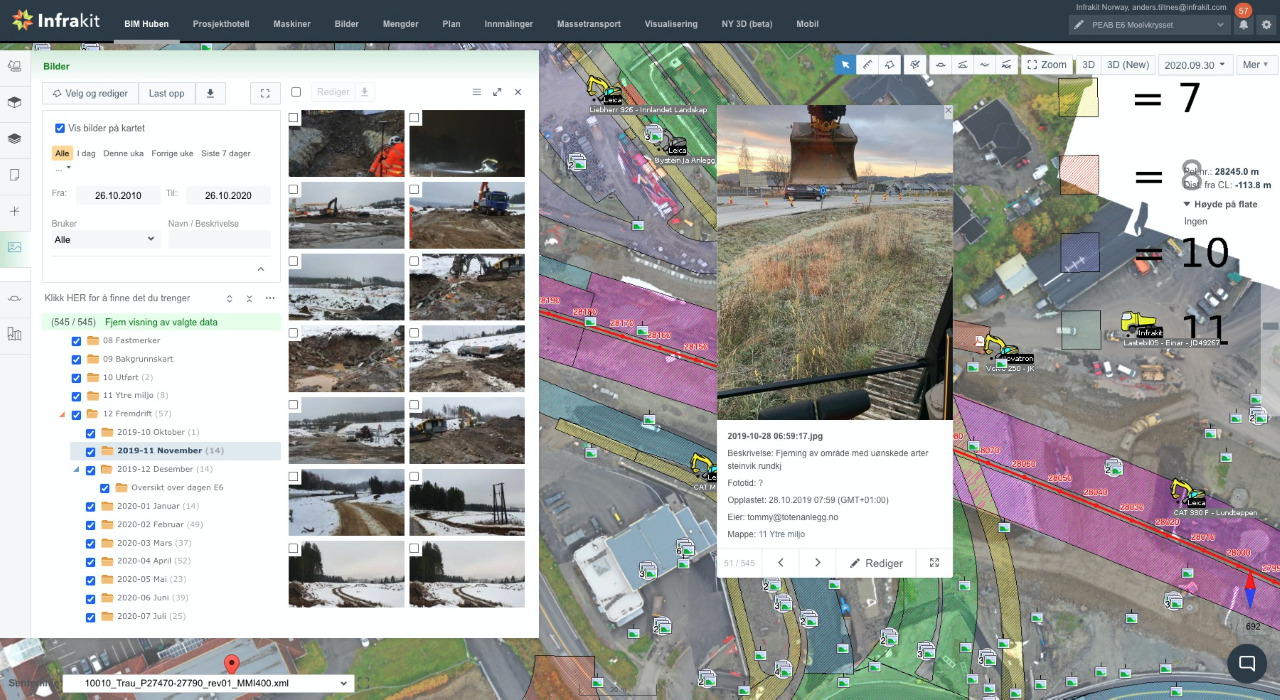

Monthly drone orthophotos used as a decision basis in meetings and for field orientation.

Project snapshot

PEAB is one of the Nordic region’s leading construction companies. For the E6 Moelvkrysset project, the team needed a setup that could handle frequent model updates, machine control distribution, and documentation across multiple stakeholders—without slowing production down.

Where Infrakit came in

Eirik Frimannslund, Survey Manager on the project, was involved in bringing Infrakit into the project from the start. The team had clear requirements for the system they envisioned:

“We wanted to have all the machine control in one place. The same applied to photos, models and the updating of new versions.” — Eirik Frimannslund, Survey Manager

After considering various alternatives, they selected the Infrakit project platform. Frimannslund first discovered Infrakit at a conference. Adoption was supported with hands-on setup and training, which helped especially for team members less accustomed to new digital tools.

What this enabled for the team

Machine control model management at scale

Before, the team had to publish the same models in several systems:“Before, we used several programs with different portals. This meant that we had to post models several times. On Infrakit they are collected.” — Eirik Frimannslund, Survey Manager

And in a turnkey-style project with many revisions:

“In a turnkey contract like this, there are many models and updates. Instead of going through five different portals, it now sticks with one.” — Frimannslund

The impact was practical and immediate:

“Overall, this provides much more efficient machine control.” — Frimannslund

Weekly calibration with traceability

PEAB runs a weekly accuracy check of machines (calibration). Infrakit supports a semi-automated workflow: the machine measures a known point, the platform stores the history, and it flags if results fall outside accuracy requirements—making it easier to catch drift early and keep production aligned.Mass transport follow-up you can trust

The team used Infrakit to monitor haulage and material fractions in real time:“Then, they can see in real time how much and which fraction has been run. With geofence, the statistics are correct as we want them.” — Eirik Frimannslund, Survey Manager

Monthly drone orthophotos for shared situational awareness

PEAB used drone orthophotos to keep a current site view that supports coordination:

“We fly once a month and make new orthophotos. Updated orthophotos provide a good basis for decisions and are used in daily meetings.” — Eirik Frimannslund, Survey Manager

It also helped more roles navigate independently:

“Chairmen, UEs and others can, for example, set simple goals themselves and orient themselves in the field via the app.” — Frimannslund

Time saved by reducing tool switching and errors

When asked about time savings, Frimannslund noted the challenge of quantifying it precisely, but the logic was clear:“It is clear that if you have to work with 5 different systems, it will increase the possibility of errors.” — Eirik Frimannslund, Survey Manager

And even without a perfect calculation:

“If it did not take five times as long, it would at least take much longer in the old fashioned way. You absolutely save time.” — Frimannslund

Why it matters

Highway and interchange projects move fast, with many interfaces, frequent model revisions, and strict quality requirements. PEAB’s experience shows the value of standardizing the production data flow—reducing portal chaos, lowering error risk, and supporting better day-to-day decisions with current site context.

What’s next

PEAB also pointed to further potential in geometric control—machines measuring completed work and automatically comparing it to design models, making quality status visible on the map and strengthening documentation of the built road. There is still potential here that isn’t fully utilized yet.

Support matters, too

In conclusion, Frimannslund said they were very satisfied with the follow-up from Infrakit—if there were any problems, they always got quick answers.